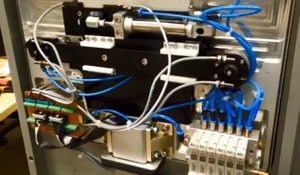

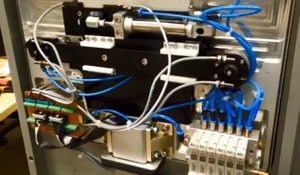

‘FOUP’ Handler For Semiconductor Wafers

Throughout the semiconductor production process,devices are initially developed on a thin disc of silicon (normally…

Read case study

Throughout the semiconductor production process,devices are initially developed on a thin disc of silicon (normally…

December 2023 TestWorks has been acquired by RailSense Solutions Ltd., specialists in IoT devices for…